Water jet cutting

Water jet

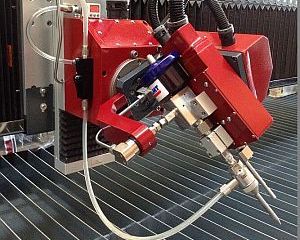

Company CHETRA SK s.r.o offers comprehensive services in the field of cutting water jet. Cutting of materials by water jet is provided by 5 axis water beam Evolution X5 from Italian manufacturer Waterjet Corporation SrL.

Within the complex services cutting water jet we offer:

- Price offer

- Processing production materials for water jet cutting

- Procurement of required material

- Water Jet Cutting

- Packing and delivery of finished products

Postup opravy:

- Demontáž armatúry

- Pieskovanie armatúry

- Výmena nefunkčných častí

- Náter alebo žiarový povlak vnútorných stien

- Zabrúsenie tesniacich plôch diamantom

- Kompletizácia armatúry

- Skúška tesnosti

- Nastavenie požadovaného otváracieho pretlaku

- Vonkajší náter armátury

- Vystavenie protokolu o oprave

Technical description the water jet of company Chetra SK s.r.o.:

Waterjet of company CHETRASK is equipped with a 5 axis 3D evolutionary cutting system with integrated touch probe, self-leveling diamond mixing chamber and anti-collision device that using the touch sensor automatically maintains a constant distance between the nozzle and the material during operation and rotation of the cutting head. Water jet is able to cut at an angle of 45 °. Maximum size of material that we can process is 4000x2000x100.

| Cutting area | Area of internal tank | Overal dimensions | Feed rate | Carrying capacity | Accuracy | Repeatibility | Ball tot 300mm | Max. cutting material thickness |

| X=2000 mm Y=3000 mm Z=300 mm A=69° C=nekoneč |

2340 mm x 4510 mm | X = 3250 mm Y = 5500 mm Z = 2520 mm |

0 - 20 mt/min | 800 kg/m2 | ± 0,05 mm | ± 0,025 mm | ± 0,05 mm | 100 - 150 mm (Depending on the material) |

Water jet cutting technology:

The technology of water jet cutting of materials using abrasive action of high pressure water jet, which acts on the material. This leads to an abrasion material, high pressure jet, carrying out a separate material. The speed of the beam reaches values twice higher than the speed of sound. These speeds achieved with the help of high-pressure pump. The nozzles are usually made of sapphire, the diameter is in the range from 0.076 to 2 mm. As the abrasive is mainly silicon carbide (SiC), aluminum oxide (Al2O3) and diamond dust.

Benefits of the technology cutting water jet:

- High cutting speed

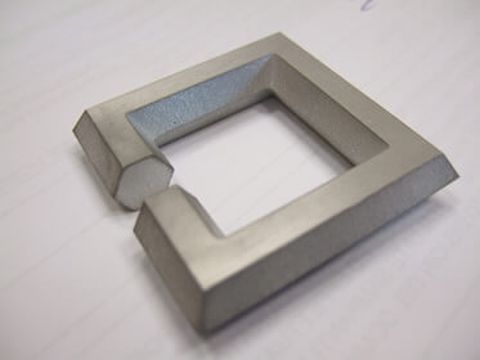

- The ability to cut flat but also complicated surface shape in the narrow tolerances

- The opportunity to manage the beam path by computer

- Waterjet can cut all kinds of materials

- The feasibility of obtaining high-precision cutting

- When waterjet there is no mechanical, chemical or physical change of the material

- When cut by a water jet will not distort the material surface

- Waterjet uses cold cut and therefore there is no heat affected material

- Waterjet cutting allows multi-layer material

- Applikovateľnosť turning, milling, drilling

Possibility of water jet using:

- Cutting hard and difficult to machine materials - titanium, tungsten, tantalum, etc.

- Cutting of composite - tungsten carbide, silicon carbide, carbon materials, etc.

- Cutting fibrous materials, plastics, asbestos, leather, gum, etc.

- Cutting wood, laminate, chipboard, etc.

- Cutting glass - plain, multilayered, bulletproof, wire, etc.

- Cutting stone - natural, synthetic, granite, marble, ceramics, porcelain, tiles, tiles, etc.