Mechanical seals according to DIN EN 12756 (24960)

Mechanical seals according to DIN EN 12756 (24960)

Type 208N

Type 208N is a robust, standardized mechanical seal with high durability even under difficult conditions. With stationary construction and protected springs (outside medium) is particularly suitable for abrasive, highly viscous media. Type 210N is economical alternative of seals 208N.

Features:

- simple

- short (L1kU)

- pressured lightweight

- both directions of rotation

- more springs (protected)

- stabile design

Limit data:

| Dw: | 28 - 100 mm 25 mm (not DIN) |

|

| 210N | 208N | |

| Pmax: | 28 bar | 50 bar |

| t: | -80°C až +260°C | |

| vmax: | 25 m/s | 35 m/s |

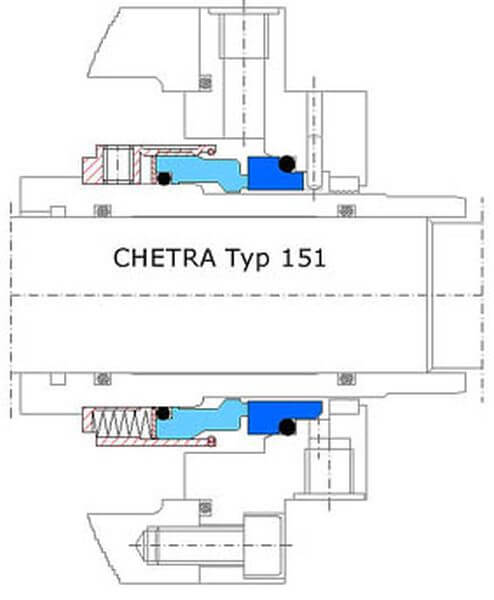

Type 151

Type 151 is a standardized rotating mechanical seal especially for pure medium, higher pressure, medium close to boiling point (light hydrocarbons) and for low temperatures.

Features:

- simple

- short (L1k)

- pressured lightweight

- both directions of rotation

- more springs

Limit data:

| Dw: | 10 - 120 mm | |

| Pmax: | 50 bar | |

| t: | -100°C až +250°C | |

| vmax: | 25 m/s |

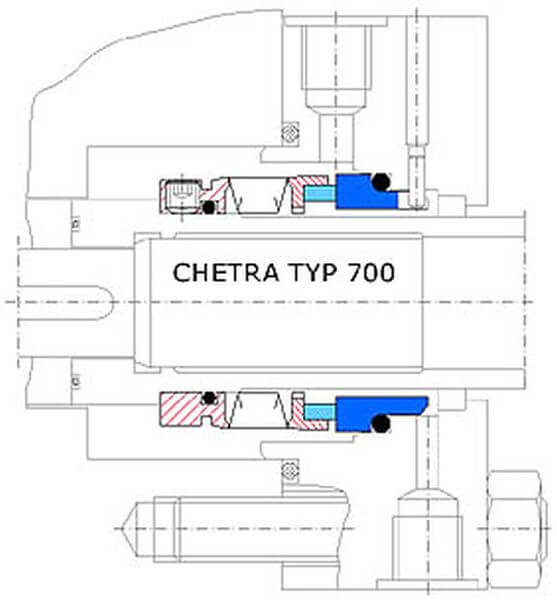

Type 700

Type 700 is a mechanical seal with metal bellows for media containing solids and for higher temperatures (blowdown, Cellulose, pulp, petrochemicals, etc.).

Further variants and versions 700 Series:

- 700H - high temperatures

- 700S - cartridge

- 770/711 - tandem double mechanical seal

- 790/791/792 - made for twin screw extruders

Features:

- simple

- short (L1kU)

- pressured lightweight

- both directions of rotation

- metall bellows

Limit data:

| Dw: | 20 - 100 mm | |

| Pmax: | 25 bar (outside) 10 bar (inside) |

|

| t: | -80°C až +315°C | |

| vmax: | 25 m/s |

Type 117

Type 117 is a short standardized double seal using a common carrier springs for internal and external mechanical seals.

Running: higher baffle pressure.

Features:

- double

- short

- pressured unlightweight

- both directions of rotation

- more springs

Limit data:

| Dw: | 18 - 110 mm | |

| Pmax: | 12 bar | |

| t: | -80°C až +250°C | |

| vmax: | 25 m/s |