Producing of metal products

Company Profile CHETRA SK s.r.o.

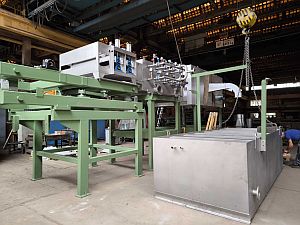

CHETRA SK s.r.o. is an engineering production company specializing in design and manufacturing of technical purpose-built equipment and steel structures according to customer specifications. The company operates in the former Kovostroj Medzilaborce industrial plant, where it started production in April 2025. The available production area is approx. 20,000 m².

Company data:

Name: CHETRA SK s.r.o.

Registered office: Sládkovičova 1937, 093 02 Hencovce, Slovak Republic

Registered office: Mierová 297/11, 068 01 Medzilaborce, Slovak Republic

Company ID: 36 497 274

Production portfolio:

- steel structures for construction industry

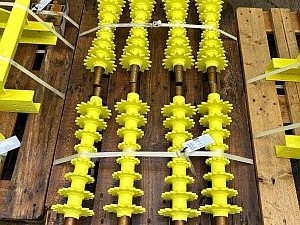

- technologies and spare parts for metallurgical industry

- equipment for powder coating and galvanizing lines

- special purpose equipment for energy and mining sector

- metal CNC components for wood industry machinery

- asphalt plant technology

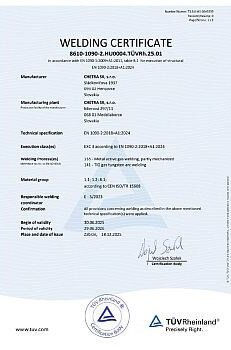

Certification:

Technical Capabilities

Our production facility in Medzilaborce is equipped for industrial-grade custom manufacturing of purpose-built technical equipment and steel structures.

Fabrication:

- overhead cranes 5 – 12.5 t

- hook height 6 – 8 m

Material Cutting

- band saws up to Ø 450 mm (square 550 × 550 mm / 610 × 350 mm)

- plate shearing up to 16 mm / width 3150 mm

- oxy-fuel cutting up to 150 mm – table 2000 × 12 000 mm

- plasma cutting up to 20 mm – table 2000 × 12 000 mm

- laser cutting: stainless / carbon steel / aluminium up to 50 mm, Cu / brass up to 25 mm – table 2530 × 6050 mm

Forming

- press brake up to 315 t / width 4000 mm

- plate rolling up to 25 mm / width 3000 mm

Machining

- turning Ø 1000 mm / length 4000 mm

- milling 4000 × 3000 × 1500 × 800 mm

- horizontal boring spindle Ø 100 – 130 mm / workpiece up to 3000 kg

- portal milling – table 2500 × 1700 × 6000 mm / workpiece up to 15000 kg

- drilling up to Ø 80 mm / workpiece height 2000 mm

- shaping height 350 mm / Ø 800 mm

- dynamic balancing Ø 1900 mm / length 4500 mm / 3500 kg

- grinding of rolls & shafts Ø 850 mm / 4000 mm

Welding

- Process compliant with EN ISO 3834-2 + EN 1090 EXC3

- Methods: 135 MAG / 141 TIG / 111 MMA / 131 MIG

- WPQR according to EN ISO 15614-1

- Material groups 1.1, 1.2, 8.1

Surface Treatment

- steel shot blasting Sa 2.5 – continuous & chamber 3500 × 2500 × 11000 mm

- glass bead blasting 2000 × 2600 × 7000 mm

- painting booth 3000 × 3000 × 12000 mm

- HVOF thermal spray

Contact:

Ing. Marek Nemčík

Production Manager

marek.nemcik@chetra.sk

+421 918 317 249