Knitted gland packing

Knitted gland packing

Type 1777MS

Type 1777MS is multiservis-seal with long-lasting, resistant to wear and protective shaft. It is a combination of PTFE-graphite fiber rigid synthetic fiber resistant to wear. It is additionally impregnated with a high proportion of lubricant. This composition ensures a high chemical resistance, low friction and resistance to abrasive materials. Its properties is designed for universal use in the pump and thanks to the good "dry run" also stirrer. In the hot water may be used up to 160 ° C without cooling!

Limit data:

| Temperature (t): | -100°C to +280°C |

| Velocity (v): | 20 m/s | Chemical durability of pH: | 0 to 14 | Pressure (p): | 30 bar for rotary pump, 60 bar for mixers |

Type 1777(GFO)

TType 1777(GFO) is an alternative type tailored to the type 1777MS. There is used patented PTFE / graphite (GFO) fiber knitted by optimal knitting techniques. The seal has a rotary pump wide range of applications with excellent thermal conductivity and chemical stability.

Admission: FMPA-Food, TÜV

Limit data:

| Temperature (t): | do +280°C |

| Velocity (v): | 20 m/s | Chemical durability of pH: | 0 to 14 | Pressure (p): | 25 bar |

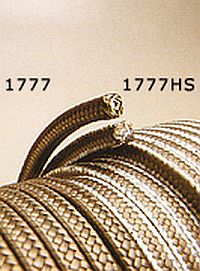

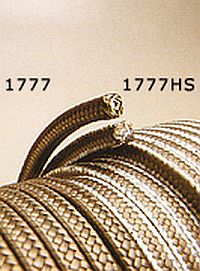

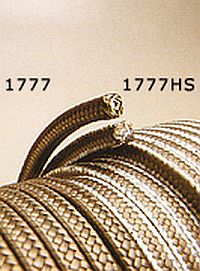

Type 1777HS

Type 1777HS is an alternative type tailored to the type 1777MS. It is a special seal for high mechanical load. This resistance is achieved by amplifying the edges TEFARA own concept, which provides high mechanical resistance PTFE-graphite seal without loss of chemical resistance.

Limit data:

| Temperature (t): | up to +280°C |

| Velocity (v): | 20 m/s | Chemical durability of pH: | 0 to 14 | Pressure (p): | 25 bar |

Type 1766

Type 1766 is a cost-effective alternative to MS type 1777 on silicone-free basis. Is a combination of PTFE multifilament fibers with PTFE-coated graphite and paraffin lubricant. Sealing a good emergency properties and is also intended for primary producers (OEM).

Limit data:

| Temperature (t): | up to +280°C |

| Velocity (v): | 20 m/s | Chemical durability of pH: | 0 to 14 | Pressure (p): | 20 bar |

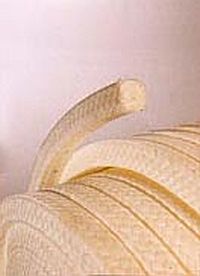

Type 1780

Type 1780 is a chemical seal in graphite ban. It is an alternative to white type 1777MS from 100% PTFE silk yarn and lubricant. It is suitable for oxidising media and in processes where it is necessary to eliminate pollution. Due to the high yielding, dense structure and lubricating properties, it is particularly suited for sealing air, gas, and control valves. It is mainly used in chemical, pharmaceutical and food industries for pumps and valves.

Limit data:

| Temperature (t): | -200°C to +280°C |

| Velocity (v): | 10 m/s | Chemical durability of pH: | 0 to 14 | Pressure (p): | 15 bar |

Type 1744UP

Type 1744UP is a versatile little maintenance protecting shaft seal. It is based on high volume aramid fiber, which is sealed when knitting a high proportion of dispersing lubricant PTFE. It is particularly suitable for medium to high solids and a dense medium, the same time protects the shaft. It is made for the piston pump in the form of knock-rings.

Limit data:

| Temperature (t): | -50°C to +280°C |

| Velocity (v): | 20 m/s | Chemical durability of pH: | 0 to 13 | Pressure (p): | 25 bar, 250 bar for piston pump. |

Type 1744

Type 1744 is a very strong wear resistant Aramid / Kevlar packing of smooth filament with PTFE dispersion and lubricants. Because "the strength of steel" suggest reinforced shaft (40-60 HRC), respectively. protective case. Applicability is in rotary pumps, valves and piston pumps. It is made for the piston pump in the form of knock-rings.

Limit data:

| Temperature (t): | -100°C to +280°C |

| Velocity (v): | 25 m/s | Chemical durability of pH: | 2 to 12 | Pressure (p): | 25 bar, 250 bar for piston pumps. |

Type 1711GS

Type 1711GS is economical GENERAL-service seal for medium load. This is the "white" seal of synthetic fibers with a high rate of dispersion and lubricant. That composition makes it suitable as an economical alternative to asbestos gaskets. Field of application is in almost all industries in general use, such as. water, waste water, weak acids and alkalis, oils, pulp and the like.

Limit data:

| Temperature (t): | -50°C to +260°C |

| Velocity (v): | 15 m/s | Chemical durability of pH: | 2 to 12 | Pressure (p): | 20 bar |

Type 1799V

Type 1799V is economical universal seal long life for valves. It is made CHETRA-knitting techniques of multifilament fiber with PTFE-graphite dispersion without oil. Long life is achieved through resistance to heat and pressure, at the minimum extrusion, good thermal conductivity and good lubricating properties. The main area of use as fittings, wherein the medium is water, hot water, chemicals, steam, oil, waste water. Exceptions are strongly oxidizing media.

Limit data:

| Temperature (t): | -200°C to +280°C |

| Chemical durability of pH: | 0 to 14 | Pressure (p): | 300 bar |

Type 1788

Type 1788 is a high performance alternative to white type 1799V. It is made from 100% pure PTFE silk fibers and is a valid alternative in situations where the graphite particles in the gland are not permitted. Seal with max. sectional density is mainly used in food, pharmaceutical and chemical industries, for special use in oxygen (up to max.200 ° C / 20 bar) and nuclear area (custom 1788 NUC CI < 100 ppm).

Admission: BAM, FMPA

Limit data:

| Temperature (t): | +280°C |

| Chemical durability of pH: | 0 to 14 | Pressure (p): | 500 bar - armatúry 800 bar - piston pump |

Type 1980

Typ 1980 high-quality self-lubricating "Carbon" Sealing with good thermal conductivity. It consists of a special carbon graphite yarn and MOS2 lubricant, thereby achieving a very good thermal conductivity and friction properties of the protecting material at higher temperatures. Its properties are also suitable for mixers.

Limit data:

| Temperature (t): | +400°C |

| Velocity (v): | 25 m/s |

| Chemical durability of pH: | 2 to 12 | Pressure (p): | 25 bar |

Type 1999

Type 1999 is a universal type of seal resistant to high temperature. It is made with a soft knitting techniques from 100% graphite fibers with dispersion of graphite. Characterized by strong resistance to most acids, alkalis, solvents, aggressive hydrocarbons, hot water, and the like. The main area of use are environments where simultaneously the required resistance to chemicals and high temperatures. Exceptions are strongly oxidizing media. Meets its properties even when used in the mixer.

Limit data:

| Temperature (t): | +500°C |

| Velocity (v): | 25 m/s |

| Chemical durability of pH: | 0 to 14 | Pressure (p): | 10 bar |